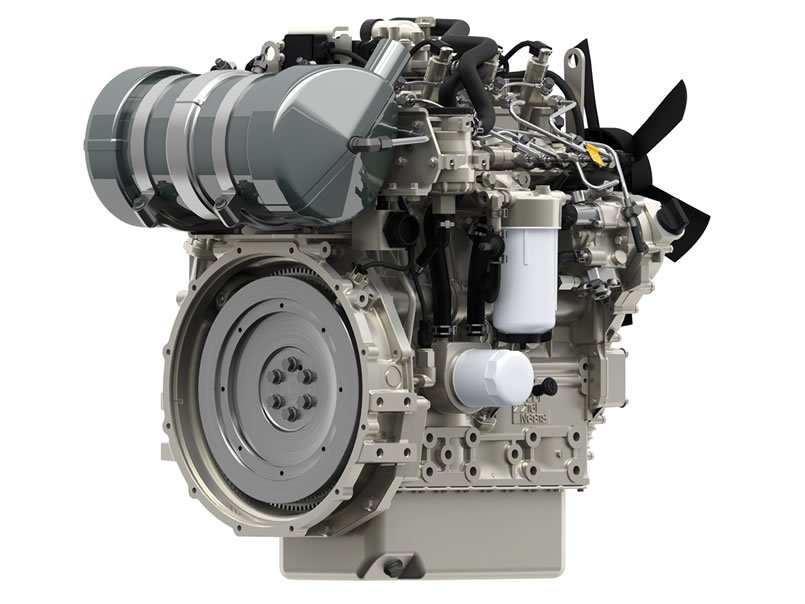

Ignoring the intricate needs of your Perkins 147 Turbo Generator is a gamble you can't afford. Regular, scheduled maintenance isn't just a suggestion; it's the bedrock of ensuring your generator delivers unwavering performance, maximum efficiency, and the long, reliable service life you expect. Without a proactive approach, you're not just risking unexpected failures; you're silently bleeding efficiency, tolerating performance drops of up to 20%, and accelerating wear on critical components.

This isn't about simply changing oil; it's about safeguarding your investment and ensuring consistent power output when you need it most.

At a Glance: Key Takeaways for Your Perkins 147 Turbo Generator

- Preventative is Paramount: Scheduled maintenance is non-negotiable for longevity, peak performance, and reliability.

- Avoid Hidden Costs: Neglect leads to unnoticed performance drops, faster wear, reduced fuel efficiency, and costly breakdowns.

- Your Manual is Gold: Always consult your engine's Operation and Maintenance Manual (OMM) for the most precise guidance.

- Hours or Calendar – Whichever Comes First: Maintenance intervals are often tied to both operating hours and time, ensuring comprehensive care.

- Daily Checks are Crucial: Simple visual inspections and fluid level checks every day prevent minor issues from becoming major problems.

- Genuine Parts Only: Insist on genuine Perkins spare parts to maintain efficiency, prevent damage, and keep your warranty intact.

- Don't Hesitate to Call Experts: For complex issues or harsh operating environments, certified Perkins technicians are your best resource.

Why Proactive Maintenance Isn't Just Good Practice—It's Essential

Think of your Perkins 147 Turbo Generator as the heart of your operation, whether it's powering a critical facility, an industrial application, or a remote site. Just like your own heart, it needs consistent care to perform optimally. When you skip a beat, the consequences can range from minor annoyances to catastrophic failures.

The core principle here is preventative maintenance. It’s about catching small issues before they snowball. Failing to do so can trigger a cascade of problems:

- Stealthy Performance Drops: Your generator might be running, but is it running well? Unnoticed performance drops, sometimes as much as 20%, can creep in, costing you power and efficiency.

- Accelerated Component Wear: Minor issues, if left unaddressed, stress other parts. A clogged filter might force the engine to work harder, accelerating wear on everything from the fuel pump to the engine bearings.

- Reduced Fuel Efficiency: A generator that isn't running optimally consumes more fuel to produce the same output, directly impacting your operational budget.

- Unexpected Failures & Downtime: This is the ultimate nightmare. A sudden breakdown during a critical operation can lead to significant financial losses, project delays, and safety concerns.

By committing to a robust maintenance schedule, you unlock tangible benefits: improved fuel efficiency, a drastically reduced risk of breakdowns, an extended engine lifespan, and crucially, consistent, reliable power output.

Your First Point of Reference: The Operation and Maintenance Manual (OMM)

Before diving into specific checks, understand that your Perkins 147 Turbo Generator comes with its own definitive guide: the Operation and Maintenance Manual (OMM). This document is your most valuable resource, containing the precise maintenance schedules tailored to your specific engine variant and its intended applications.

If you don't have your OMM, contact a Perkins 147 turbo generator details distributor immediately. They can provide you with the correct manual or guide you to where you can download it. While this article provides general best practices, always defer to your OMM for the most accurate and up-to-date information for your unit.

Decoding Your Maintenance Schedule: Hours vs. Calendar

Perkins provides maintenance schedules that factor in both engine running hours and calendar time. This dual approach ensures that even intermittently used generators receive the necessary care. For instance, an instruction might read "coolant change every two years or 3,000 hours, whichever occurs first."

This means:

- If your generator hits 3,000 hours in 18 months, you change the coolant then.

- If your generator only logs 500 hours in two years, you still change the coolant after two years.

This "whichever occurs first" rule is vital and applies to many scheduled tasks. Keep an accurate log of both running hours and the date of your last service.

The Daily Ritual: Non-Negotiable Checks

Many generator owners overlook daily checks, thinking they’re too minor to matter. This is a critical mistake. Daily inspections are your first line of defense, catching nascent issues before they escalate. They are quick, simple, and can save you from significant headaches down the line.

Here’s what you should be checking every single day your generator is in operation, or before its first run of the day:

- Cooling System Coolant Level: Ensure the coolant level is between the 'low' and 'full' marks on the expansion tank. Low coolant can lead to overheating, which is a major engine killer.

- Driven Equipment: Inspect any equipment directly driven by the generator. Look for loose connections, abnormal noises, or signs of wear.

- Engine Air Cleaner Service Indicator: Check the indicator. If it shows the filter needs servicing (often a red flag or a visible change), address it promptly. A restricted air filter starves the engine of air, reduces power, and increases fuel consumption.

- Engine Air Pre-cleaner (if fitted) Cleaning: If your generator has a pre-cleaner, clear out any accumulated debris. This prolongs the life of the main air filter.

- Engine Oil Level: Check the oil level using the dipstick. It should be between the 'add' and 'full' marks. Low oil can cause severe engine damage. Always top up with the correct specification oil.

- Fuel System Primary Filter/Water Separator: Inspect the primary filter/water separator bowl. Drain any water or sediment present. Water in the fuel system is detrimental and can lead to corrosion and fuel system component failure.

- V-belts: Check the tension and condition of all V-belts (e.g., alternator, cooling fan). Look for cracks, fraying, or excessive slack. A slipping or broken belt can quickly lead to overheating or loss of charging.

- Walk-Around Inspection: This might sound simple, but it’s incredibly effective. Walk around the entire generator. Look for:

- Leaks: Any drips of oil, fuel, or coolant on the ground or engine block.

- Loose Connections: Wires, hoses, clamps, fasteners.

- Abnormal Noises or Vibrations: While running, listen for anything out of the ordinary.

- Unusual Smells: Burning oil, fuel, or electrical smells.

- Blockages: Ensure air inlets and outlets are clear of debris.

- General Cleanliness: A clean generator allows easier identification of leaks and issues.

Intermediate Milestones: Weekly & 250-Hour Services

Beyond the daily checks, your Perkins 147 Turbo Generator requires more in-depth attention at regular intervals. These services are designed to address wear on consumables and ensure system integrity.

Every 50 Service Hours or Weekly: Drain Fuel Tank Water and Sediment

Regardless of how many hours your generator runs, dedicate time each week (or after every 50 hours of operation) to drain any accumulated water and sediment from the fuel tank. Fuel quality is paramount, and condensation or contaminants can settle at the bottom of the tank. Regular draining prevents these from reaching your delicate fuel system components.

Every 250 Hours: Oil and Filter Replacement (Generators Specific)

For generators, the 250-hour mark is a critical service interval for lubrication system maintenance.

- Engine Oil Change: The engine oil is the lifeblood of your generator. Over time, it degrades and accumulates contaminants, losing its lubricating properties. Changing the oil every 250 hours (or as specified in your OMM for your specific model and oil type) is crucial. Always use the specified grade and type of oil.

- Engine Oil Filter Replacement: Along with the oil, the oil filter must be replaced. A clogged filter cannot effectively remove impurities, allowing them to circulate and cause wear.

This 250-hour interval is specifically tailored for generators, which often operate under consistent load for prolonged periods, making regular oil and filter changes even more vital than for some general engine applications.

The Backbone of Reliability: 500-Hour & Major Services

As your generator racks up more hours, the maintenance becomes more comprehensive, moving into what Perkins refers to as 'minor' and 'major' service intervals.

Every 500 Hours: Minor Services, Air and Fuel Filter Replacement (Generators Specific)

The 500-hour mark typically represents a minor service for general engines, but for generators, it includes essential filter replacements that are vital for clean air and fuel delivery.

- Air Filter Replacement: The air filter protects your engine from dust, dirt, and debris. A clean air filter ensures optimal combustion and prevents abrasive particles from entering the engine cylinders, which would lead to premature wear. Even if it looks clean, replace it at this interval as its filtering efficiency degrades over time.

- Fuel Filter Replacement: Fuel filters trap contaminants and water before they reach the precision components of your fuel injection system. Replacing them prevents blockages, maintains fuel flow, and protects injectors and fuel pumps from damage.

- General Inspection and Adjustments: This interval is also a good time for a thorough visual inspection of hoses, clamps, wiring, and fan belts. Check and adjust belt tensions as needed.

Perkins schedules major service intervals in multiples of 500 hours, meaning you’ll have significant check-ups at 1,000, 2,000, 3,000, and 4,000 hours, building upon these core tasks.

Beyond the Basics: 1000-Hour Inspections & Load Testing

When your Perkins 147 Turbo Generator reaches 1,000 hours of operation, it's time for a more in-depth assessment that goes beyond routine fluid and filter changes. This comprehensive service helps to identify potential issues that might not be visible during daily or shorter interval checks.

Every 1000 Hours: Full Inspection, Load Testing, and Injector Checks (Generators Specific)

This major service interval for generators is critical for maintaining peak performance and diagnosing any emerging issues.

- Full Inspection: This involves a much more detailed visual and tactile inspection of the entire generator system. Technicians will typically check:

- Engine mounts for signs of wear or damage.

- All electrical connections for corrosion or looseness.

- Turbocharger for shaft play or damage (given it's a "turbo generator").

- Exhaust system for leaks or cracks.

- Cooling system hoses and clamps for integrity.

- Radiator fins for blockages or damage.

- Load Testing: This is a crucial diagnostic step. The generator is run at its rated capacity (or as close as possible) for a specified period. This helps to:

- Verify the generator’s ability to handle its maximum load.

- Identify potential overheating issues under stress.

- Confirm voltage and frequency stability.

- Burn off wet stacking (unburnt fuel and oil residue that can accumulate when a diesel generator consistently runs below its optimal load).

- Assess engine performance under real-world conditions.

- Injector Checks: Fuel injectors are precision components vital for efficient fuel delivery. At this interval, they should be inspected for proper spray patterns, signs of clogging, or excessive wear. Faulty injectors can lead to reduced fuel efficiency, increased emissions, and poor engine performance. Depending on findings, cleaning or replacement may be necessary.

This 1000-hour service is often best performed by certified technicians who have the specialized tools and diagnostic equipment to conduct these checks thoroughly.

The Non-Negotiable: Genuine Perkins Parts

You wouldn't put generic, unproven components into a high-performance machine, would you? The same principle applies unequivocally to your Perkins 147 Turbo Generator. The use of genuine Perkins spare parts is not merely a recommendation; it is absolutely critical for the health and longevity of your unit.

Here’s why you should never compromise on genuine parts:

- Engineered to Exact Specifications: Genuine Perkins parts are designed, manufactured, and tested to the precise specifications of your engine. This ensures perfect fit, form, and function, guaranteeing optimal performance and compatibility. Non-genuine parts might look similar but often fall short in material quality, tolerances, or design, leading to unforeseen issues.

- Prevents Damage: Using sub-standard or counterfeit parts can directly damage your generator. An ill-fitting filter might allow contaminants to pass through, grinding away at engine internals. A poorly manufactured belt could snap, causing immediate system failure.

- Maintains Efficiency: Genuine parts ensure that every system operates as intended, contributing to the generator's designed fuel efficiency and power output. Non-genuine parts can compromise these, leading to higher running costs and reduced performance.

- Protects Your Warranty: Most manufacturers, Perkins included, explicitly state that using non-genuine parts will void your warranty. This leaves you vulnerable to expensive repairs should an issue arise.

- Reliability You Can Trust: When you install a genuine Perkins part, you install confidence. You know it has undergone rigorous testing and meets the high standards expected of the brand.

What kind of parts are we talking about? This isn't just about big components. It includes, but is not limited to: - Filters: Oil, fuel, and air filters are meticulously designed to capture specific particle sizes and withstand operational pressures.

- Belts: Engineered for correct tension, flexibility, and longevity in your engine's environment.

- Fuel Injectors and Pumps: Precision components where even slight deviations can have major impacts on engine performance and emissions.

- Cooling System Components: Thermostats, water pumps, and hoses designed to handle the specific heat and pressure profiles of your Perkins engine.

- Electrical and Control Parts: Sensors, relays, and modules that communicate vital information and control critical functions.

Always source your spare parts from an authorized Perkins distributor. They are your trusted partner for genuine components and expert advice.

Navigating Harsh Environments & Seeking Expert Care

While a diligently followed maintenance schedule covers most scenarios, some operating conditions demand an extra layer of vigilance and, often, professional intervention.

When to Bring in the Experts

- Harsh Operating Environments: If your generator operates in extremely dusty, humid, hot, cold, or corrosive conditions, standard maintenance intervals might need to be adjusted (often shortened). These environments accelerate wear and tear, necessitating more frequent checks and replacements.

- Unusual Symptoms: Any persistent unusual noises, vibrations, smells, smoke, or performance issues that you can't identify or resolve with basic troubleshooting warrant immediate attention from a certified technician. Don't guess; get an expert opinion.

- Complex Diagnostics: Modern generators are sophisticated machines. Many diagnostic procedures, especially those related to the turbocharger, fuel injection system, or electronic controls, require specialized tools and software that only certified technicians possess.

- Tailored Maintenance Plans: For operations with unique demands, a certified Perkins technician can help tailor a maintenance plan that goes beyond the standard schedule, ensuring your generator receives optimal care for its specific operational profile.

- Major Service Intervals: While some routine tasks can be done in-house, major services like the 1000-hour inspection, load testing, and precise injector checks are best left to professionals. They ensure thoroughness and proper calibration.

Finding Certified Technicians:

Always contact an authorized Perkins distributor for maintenance issues or to obtain new service schedules. They have access to factory-trained, certified technicians who understand the intricacies of your Perkins 147 Turbo Generator. These experts ensure that all work is performed according to Perkins standards, using genuine parts and proper procedures.

Common Questions About Perkins 147 Turbo Generator Maintenance

You've got questions, and we've got answers. Here are some of the most frequently asked questions regarding Perkins 147 Turbo Generator maintenance:

Q: Can I use generic oil or filters to save money?

A: While it might seem like a cost-saving measure in the short term, using generic oil or filters can significantly reduce your generator's lifespan, decrease efficiency, and potentially void your warranty. Genuine Perkins parts and recommended oil specifications are engineered to work perfectly with your engine, ensuring optimal performance and protection. The long-term costs of premature wear or breakdown far outweigh any initial savings.

Q: How often should I run my generator if it's mostly on standby?

A: Even standby generators need to be run regularly under a load (at least 30% of its rated capacity) to prevent issues like "wet stacking" and ensure all systems are operational. Consult your OMM, but a common recommendation is weekly or bi-weekly for at least 30-60 minutes. Remember, the "whichever occurs first" rule for maintenance intervals still applies – calendar time is important even if running hours are low.

Q: What is "wet stacking" and how does maintenance prevent it?

A: Wet stacking is the accumulation of unburnt fuel and carbon deposits in the exhaust system, often due to a diesel generator running at low loads for extended periods. This can lead to reduced efficiency, increased emissions, and damage. Regular load testing (as part of the 1000-hour service, for example) burns off these deposits, keeping your generator clean and efficient. Properly sized generators and appropriate running protocols also help prevent it.

Q: My generator is making a new, unusual noise. What should I do?

A: Any new or unusual noise is a warning sign. Stop the generator immediately (if safe to do so) and perform a thorough visual inspection for loose components, leaks, or obvious damage. If you can't identify the source or resolve the issue, contact a certified Perkins technician. Continuing to run a generator with an unknown noise risks further, potentially catastrophic, damage.

Q: Is it okay to skip a minor service if the generator hasn't been used much?

A: No. While running hours are a key factor, calendar time is equally important. Fluids degrade, seals can dry out, and components can corrode even when stationary. Adhering to the "whichever occurs first" rule for both hours and time-based intervals ensures your generator remains in optimal condition, ready to perform when called upon.

Q: How do I know if my coolant is still effective?

A: Simply checking the coolant level isn't enough. Coolant has a limited lifespan, after which its anti-corrosion and anti-freeze properties diminish. Your OMM will specify the change interval (e.g., every two years or 3,000 hours). You can also use test strips to check the condition and concentration of your coolant, but ultimately, replacement at the recommended interval is the most reliable approach.

Putting It All Together: Your Proactive Maintenance Strategy

Maintaining your Perkins 147 Turbo Generator isn't a chore; it's a strategic investment. By embracing a proactive, diligent approach to its care, you're not just preventing breakdowns, you're ensuring the consistent, efficient, and long-lasting performance that your operations depend on.

Here’s your actionable strategy:

- Embrace Your OMM: Make your generator's Operation and Maintenance Manual your most trusted companion. It contains the precise schedule and instructions for your specific unit.

- Log Everything: Keep meticulous records of running hours, service dates, and all maintenance tasks performed. This helps you track intervals and identify any recurring issues.

- Perform Daily Checks: Don't underestimate the power of a quick visual inspection and fluid check. These small efforts prevent major headaches.

- Adhere to Intervals (Hours & Time): Always follow the "whichever occurs first" rule for all scheduled services.

- Insist on Genuine Parts: Never compromise on the quality of your spare parts. Genuine Perkins components are engineered for optimal performance and protection.

- Don't Fear the Experts: For complex diagnostics, major services, or unusual symptoms, always consult certified Perkins technicians. Their expertise is invaluable.

- Consider Your Environment: If your generator operates in harsh conditions, discuss a tailored maintenance plan with your Perkins distributor or certified service provider.

Your Perkins 147 Turbo Generator is a powerhouse designed for reliability. With a commitment to smart, scheduled maintenance, you'll ensure it lives up to that promise, delivering peace of mind and power for years to come.